Vitrek 951I

Electrical Safety Compliance Analyzer, 6 kV, AC/DC/IR/LR

The Vitrek 951I 6kVAC/DC/IR/LR Electrical Safety Compliance Analyzer offers high power, speed, accuracy, and resolution for better hipot testing. The resolution down to 100 pico-amps allows for critical leakage current measurements. Up to four 64 channel HV scanners can be directly controlled with this unit.

- AC Hipot: 20V - 6kV

- DC Hipot/IR: 30V - 6.5 kV

- Built-in phase angle measurement displays both resistive leakage current/reactive leakage current

- 6KV AC/DC/IR/LR Electrical Safety Compliance Analyzer

- Dual Dimensional/Test Specific Broadband ARC Detection

- Built-in operator safety features: automatic shutoff and recessed start switch

- Holds up to 100 tests with up to 100 steps per test

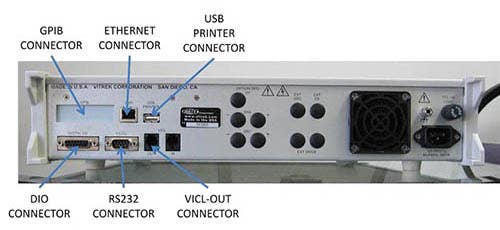

- Tests can be selected via front panel, Ethernet, RS232, Digital I/O

- 4-Wire Milli-Ohmmeter Function provides fast, accurate 5 digit resistance measurements

- Ethernet, RS232, Digital I/O, USB Printer, and Scanner Control

- High Voltage Scanner Control-up to 256 point switching capability with available 964i HV Scanners

- Dual Coldfire® microprocessors combined with Dual DSPs provide Ramp rates up to 50KV/second

- Capacitance Test Modes

- 3 IR test modes: end on time, end on pass or end on fail

- Light Weight Switching Power Supply Design

- Dimenions: 3.5 in. H x 17 in. W x 18 in. D

- Compatible with most 19 in. rack enclosures

- Safety Tested per EN 61010-1. EMC compliant to EN 61326-1

The Vitrek 951i Electrical Safety Compliance Analyzer, 6 kV, AC/DC/IR/LR combines high output power, with a wide range of AC and DC voltage outputs and extremely low leakage current measurement. This model offers 50mA of source current for DC Hipot, providing the power needed to rapidly charge and discharge challenging DUTs. The 951i adapts itself to the load automatically. This model offers load capacitances up to a farad during DC withstand testing and highly inductive loads when low resistance testing. The 951I is able to directly control up to four 64 channel HV scanners, up to 256 test points. When using a PC with Vitrek's QuickTest Pro software, the count expands up to 640 test points.This model is not only capable of testing that a DUT does not breakdown, but it is also capable of testing that a surge suppressor type device does breakdown at the correct voltage.

The 951i excels at making critical leakage current measurements, due to its resolution down to 100 pico-amps. This high resolution provides built-in insulation resistance measurement (IR) up to a Tera-ohm, add an optional 4-wire milli-ohmmeter with autoranging up to 100K ohm and an optional 40 amp Ground Bond function. Built-in Phase Angle measurement allows the measurement and display of both resistive (in-phase) leakage current and reactive (out-of-phase) leakage current caused by capacitive coupling.

Safety features include GFI High speed shut down for earth ground leakage faults, high speed shut down output for interruption of safety interlock, and TLSS™ Test Lead Safety Sense, which clamps DUT chassis near ground by continuously verifying proper connection of test leads prior to and during HV testing. The recessed start switch of the 951I prevents inadvertent actuation.

The 951I offers additional features including Multi-Dwell Functionality and Ramp High/Dwell Low Current Limits. Multi-Dwell Functionality permits dwells at different voltage levels without having to return to zero between test steps - dramatically simplifying advanced analysis of dielectric properties. Ramp High/Dwell Low Current Limits permits the user to set separate limits for the ramp and dwell providing faster ramp times and lower leakage test limits.

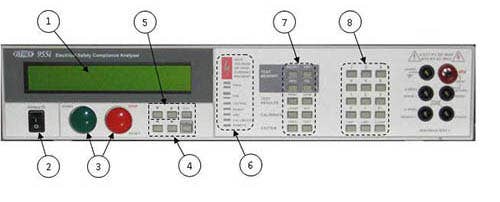

1. The display. This shows all menus during interactive data entries, all measurements during a test, and the present date/time when not performing any other duties.

2. The power switch. This turns on/off the power to the 951i.

3. The start and stop buttons.

- a. The start button allows the user to start performing a previous selected test sequence, or (while running a test sequence) select to continue a test step when it is waiting for the user to do so.

- b. The stop button aborts any test sequence in progress (while running a test sequence), aborts the menu activity in progress discarding any changes made (while performing a menu), or makes no test sequence selected (otherwise).

4. The menu selection keys. During all menus, the selected element of the menu is highlighted by flashing between the data and blocks. These keys allow the user to move the selection point within a menu.

- a. The Left and Right Arrow keys are used to move the selection point within a menu.

- b. The enter key is used to finish entry of a menu data and automatically move to the next menu item.

- c. The exit key is used to save all changes made within a menu and return to the previous menu (if any) or to the inactive display.

5. The edit keys. These allow the user to decrement or increment a selected menu items' value. During numeric entry these initiate "edit" mode of data entry, rather than "direct" mode of data entry (i.e. allow the user to adjust the existing entry using the Up/Down Arrow keys, rather than overwriting the existing value with a new value using the numeric keys). For convenience, these keys auto-repeat if the user maintains pressure on them.

6. The indicators.

7. The menu keys. These initiate a menu allowing the user to perform certain activities via the front panel of the 951i. Many of these can be disabled by the user by requiring a password in order to utilize them.

8. The data entry keys.

Expanded Capabilities via QT Insite Test Automation Software

For users looking to manage their testing and improve throughput, safety, and quality, the QT Insite Test Automation Software License is available for separate purchase.

The QT Insite Software enables users to automatically initiate tests, then collect and store the results data. Test results can be tracked by part number and changes in performance can be shown by lot number. Barcode scanning allows users to recall the ready-to-run sequence of a specific DUT and multiple DUT numbers can be linked to a given sequence. With this software, the results of every test are recorded. Test results can be easily recalled and saved in the format of .pdf or .csv for quick reference along with the ability to print the reports out. Individual tests can be recalled for auditing purposes. The QT Insite Software provides a clean and intuitive means for creating or modifying up to 999 electrical safety test sequences which includes AC and/or DC voltage withstand, insulation resistance, and ground bond testing. For users in the medical, automotive, aerospace, and manufacturing industries, the QT Insite Software expands upon the capabilities of the user's instrument in order to provide fast and accurate test results for ensured system safety and reliability.

| Vendor Alias | 951I |

|---|---|

| Country of Origin | United States |

| Brand | Vitrek |

| Condition | NEW |

- 1 - TL-209 Test Lead Set

- 1 - Power Cord

- 1 - Operating Manual

- 1 - QTPro II-950 45 day free trial

- 1 - NIST Traceable Calibration Certificate without data